Aussie Locker

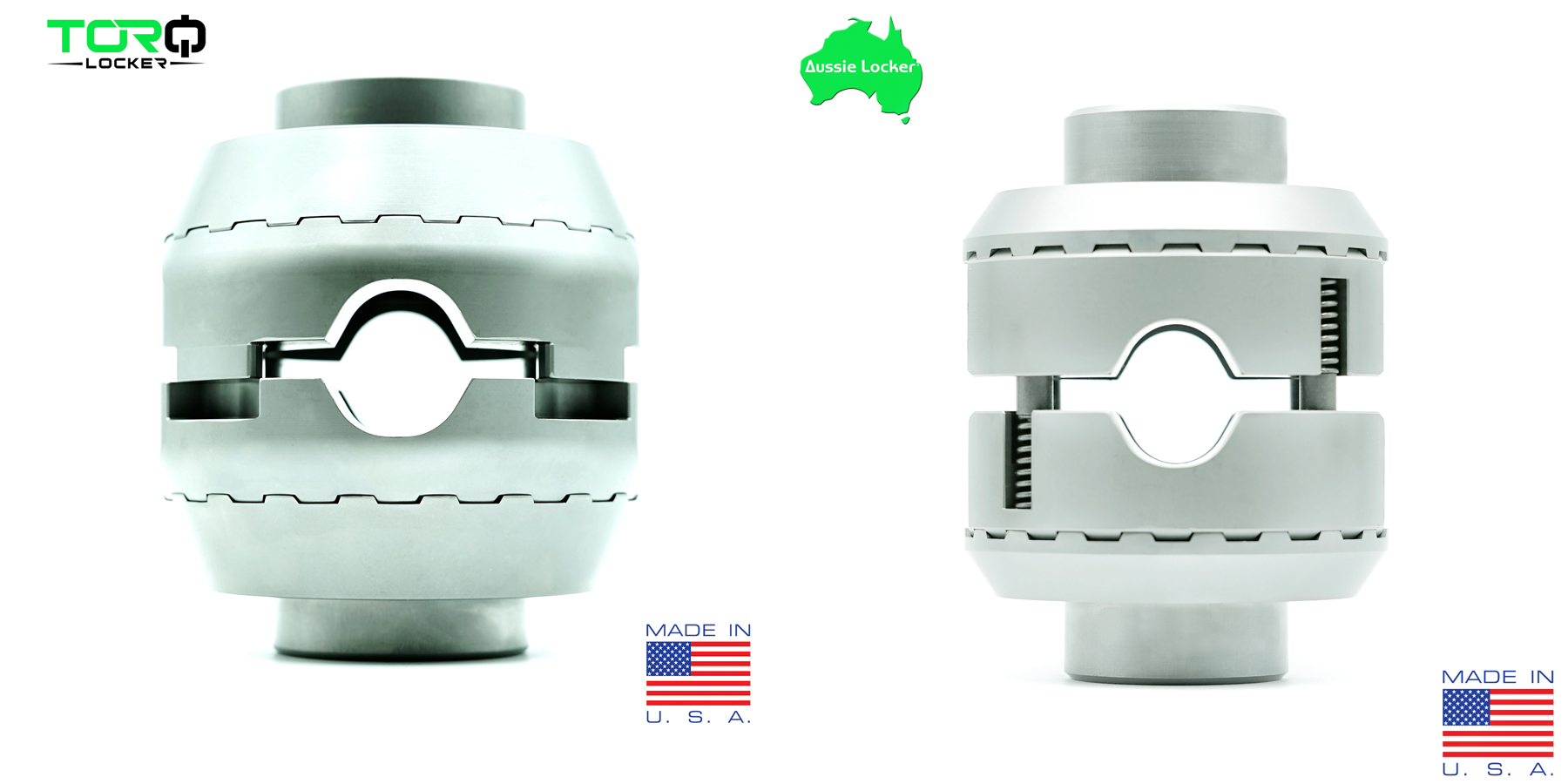

Aussie Locker vs TORQ Locker

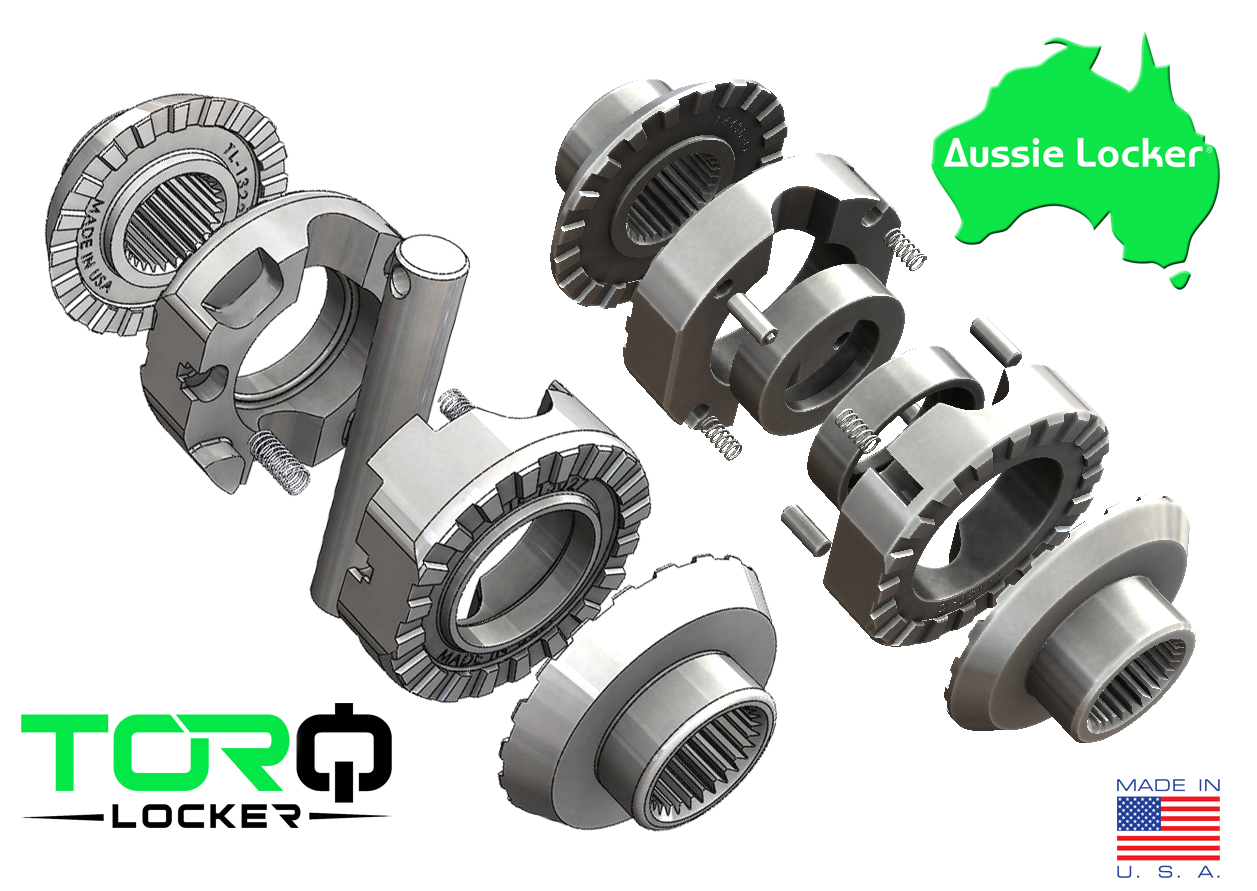

Both models mechanically function the same, providing traction to both tires while allowing for wheel speed differentiation automatically. They are both Made In USA from 9310 - hardened alloy steel, and replace the spider gears in your stock, open style differential. Both are the only automatic lockers made in the USA.

The Aussie Locker is our tried and true design. We've been manufacturing it since 2003. Aussie has a 2 year warranty, has 2 spacers that keep the axle gear and cam gear on axis. The Aussie uses dowel pins to align the 2 cam gears while the locker is ratcheting. The Aussie Locker is very budget friendly.

The TORQ Locker is the strongest design on the market! With NO SPACERS, NO PINS, and a 4 Year Warranty. The TORQ Locker has better on-road manners due to no spacer bind, which is most noticeable in a rear locker application. Spacers, as seen in all other automatic drop in lockers can slide down the axle and bind on the cross pin, making the occasional "bang" lunchbox lockers are known for. The TORQ Locker has no spacer and therefore is much quieter on the road.

Both the Aussie Locker and TORQ Locker are precision made automatic lockers that will give you years of traction. Bottom line, Aussie is proven, and budget friendly. TORQ is our premium line and has design features that improve strength and on-road manners. TORQ has a 4 year warranty and is on average about 100€ more than Aussie.

Design differences:

General Information

The Aussie Locker is a fully automatic and precision manufactured automatic differential locking device that does not require any manual operation to activate. It does not require any switches, external compressors, electrical cables, air lines, or pneumatic controls. The Aussie Locker relies on a simple and highly innovative mechanical design which makes use of two distinct sets of forces, "ground driven" forces acting on a wheel when cornering (forces the outside of the wheel to turn faster) and the engine driven forces through the drivetrain. The combination of these two sets of opposing forces and the unique Aussie Locker design allow the automatic locking and unlocking of the driving gears when a vehicle turns or requires differential action.

How the Aussie Locker is different from a standard differential

A standard differential is designed to perform two main traction related operations; Transmit engine power via the drive line to the wheels, Allow differential action (allow the wheels to travel at different speeds) to allow cornering without drive train damage or tire damage. The traditional differential design allows for an infinitely variable rate of differentiation ranging from 50:50 where both wheels turn at the same speed (straight line driving) and a ratio of 100:0 where one wheel spins freely and the other is not driven at all (not what you want to face when off roading). The traditional differential also allows for all power to be transmitted to the "path of least resistance" which is fine on highways because both wheels have some degree of traction but off-road you often require substantial power and in this case even a small difference in traction can result in wheel spin and the subsequent loss of traction.

A limited slip (LSD) differential is simply a standard differential (also called open) with either a fixed bias or dynamic biasing mechanism which serves to only "partially" lock up" the two axles by way of clutch plates or special gear design. However, most require that both wheels still have some traction on the ground to operate and even when new will cause a wheel in the air to spin uncontrollably so as to be completely ineffective where off road traction is required. The Aussie Locker overcomes the traction deficiency of the standard differential and a limited slip differential so as to ensure that 50:50 power split is achieved when driving irrespective of ground conditions, yet still allowing differential action when required.

Simple explanation of the Aussie Locker operation

The Aussie Locker mechanism allows a wheel to turn faster than the speed of the differential that is driving it (differentiation), but never allows a wheel to turn slower than the speed the differential and engine is turning it (traction). Therefore, a wheel cannot ever stop turning if the engine is driving it, but in a corner it can be forced to actually turn faster. Unlike a standard differential, the engine can never drive one wheel faster than the other.

100% positive locking

The Aussie Locker is positive locking, meaning there is no slippage when locked. There is a mechanically solid engagement of all parts. In contrast a limited slip differential is not positive locking and does allow slippage and one wheel "spin up" i.e. the spinning of one wheel at twice the differential speed while the other wheel having traction remains motionless. With the "Aussie Locker" you always get 100% of drive and traction to both wheels.

Dynamic Locking Principle

Unlike some other types of lockers, the Aussie Locker has a locking and unlocking principal that is dynamic. Dynamic in that the more power that is applied, the harder it locks so it doesn't need large bias forces operating on it to keep it locked. The bias spring forces are minuscule and can easily be compressed with two fingers. This results in a locker that is able to lock and unlock easily even when driving on extremely slippery surfaces like mud and wet grass. The locking mechanism is so sensitive that a wheel can be disengaged with one finger when a wheel is jacked up, off the ground. The "Aussie Locker" engineering philosophy is based on two sets of opposing forces but simplified over other automatic locker designs. Basically there are two forces acting on the two gear sets. One acting to unlock the cam and axle gears by the gear tooth design and effects of the ground driven forces acting on a wheel when cornering. The other is acting to lock the cam and axle gears due to the camming action of the cross shaft and axle gear due to the 4-dimensional spiral cut cam grove with bearing surfaces under the effects of engine power. Depending on the situation, the locker can either uncouple the driving gears i.e. if the differential force is acting on a wheel to turn it faster than the wheel is being driven by the differential and engine, then that side can freely disengage and unlock providing differential action. When driving on road, ground driven forces is always exceeding engine power, it’s really rare to make a wheelspin while driving in hard ground (burnout during movement) so locker always enable deafferentation of wheels.

Load transfer and strength

The Aussie Locker design uses a large number of very low profile teeth which collectively do all the ramping and the driving. Engine power is transferred through the flats of all 20 teeth at the same time rather than the original standard differential which has only 2 or 4 teeth driving at a time with all the force being transmitted between two points on the curved surface of the pinion and side gear teeth. The Aussie Locker Has 2-5 times greater surface area over which to transfer the engine power. This means that the Aussie Locker can handle engine power often found in modified off road vehicles with large tires. The design of the locker result in the gears being locked when driving vs. the slipping and sliding that occurs when traditional spider and side gears turn and mesh.

Constant 4WDs

Like all automatic lockers, the Aussie Locker cannot be used in front axles of constant (not selectable) 4Wheel Drive vehicles. Some vehicle manufacturers offer a part-time (selectable) 4WD option and automatic lockers can be installed. Some vehicle owners install part-time kits or use free wheeling hubs. Free wheeling hubs are anyhow a desired addition to SUV if it’s mainly driven on-road. They improve fuel consumption (axle shaft and differential rotating) and manoeuvrability.

High-strength, ultra-resistant alloy made in the USA

The Aussie Locker is made from an hardened 9310 alloy steel from mills in the USA.

TECH NOTE: All Aussie Lockers are designed for installation in an open differential. The Aussie Locker will not work in posi or limited slip carriers.

Frequently asked questions (FAQ)

Can I tow a trailer?

Yes you can, the Aussie Locker will not affect your trailer towing ability. You will find that the dramatic improvement traction will come in handy when pulling the boat up the ramp or anytime where increased traction is important.

What about large tires?

We do not have exclusion in our warranty covering locker use in vehicles with over sized tires. Generally the biggest issue with over sized tires is the diameter of the tires themselves.

Tires should always be run at the tire pressure recommended by the manufacturer. The diameter of the tires should be within 10mm of each other on the same axle. If one tire has a larger diameter either from pressure difference or manufacturing variances it will cause the locker to constantly lock and unlock creating excessive wear and this will void the warranty. Replace any tire that is outside of the recommended tire diameter allowance.

Another area to consider when installing a locker in a vehicle with over sized tires is that this type of setup puts significantly greater stress on the original equipment manufacturers components in the differential. The locker is designed to withstand these stresses but should another component fail, and the locker is damaged, the locker is not covered under warranty. Under no circumstances does Torq-Masters Technology, Inc, warranty cover parts that we do not supply as part of the order.

Will it wear out my tires?

No, the smoothness of the “Aussie Locker” results in no measurable tire wear. The gain in traction should increase tire life due to the reduction of tire spin. Reduction in tire spin results in less trail damage.

Can I use the Aussie Locker with high-powered motors?

Yes, the design and materials used in the “Aussie Locker” allows it to operate with high power.

Will it weaken my diff?

No. The “Aussie Locker” shares the load evenly between the wheels which prevents wheel spin. Wheel spin can damage a diff when a spinning wheel obtains sudden traction. The automatic action of the “Aussie Locker” prevents excessive drive line windup. Drive line wind up is common in other locker designs.

Can I fit an Aussie Locker in my 2WD vehicle?

Yes, the traction improvement in a 2WD vehicle is the same as in a 4WD installation.

Do I need special oil or lubricant?

No, use the manufacturers recommended fluid for the diff in your vehicle.

Will this affect my gear ratio? What about thick ring gears in differentials modified from the OE gear ratio?

No, the Aussie Locker does not affect the gear ratio Some thick ring gears (4.56 for example) may interfere with the installation of the cross pin. If you run into this problem we recommend grinding on a tooth in an unused area of the ring gear rather than grinding on the cross pin. Contact info@gear4offroad.eu if you have any questions regarding the grinding location and depth.

How long will it take to install?

Depends on the model and who is doing the job. As a guide you should expect 1-2 hours for most rear installations. For front diffs the time is usually 2-3 hours

IFS front installations take longer.

What if I have a limited slip or posi diff now?

You will need to replace the limited slip or posi carrier with an open carrier. Open carriers are available at auto salvage yards, on bulletin boards and at aftermarket diff parts retailers.

How long will it last? Does it wear out quickly?

The steel alloy and proprietary heat treatment process used in making the USA manufactured Aussie locker results in a gear set that is twice as hard as the gears it replaces. Properly installed and maintained the Aussie locker will provide years of trouble free service.

Why is it called an automatic locker?

The “Aussie Locker” design is automatic in that there are no actions required by the driver to actuate the locking capability. The locker is always locked and unlocks in turns when the outside wheel overruns the speed of the inside wheel.

There are no cables, electrical wires, air lines, pneumatic or external connections of any kind required.

Can I install in a constant 4WD vehicle?

It is possible to install the “Aussie Locker” in the front or rear of all open differential vehicles. It is not possible to install the locker in the front differential of permanent constant 4WD vehicles without installing free-wheeling hubs, or otherwise converting the part-time 4WD. Some Jeeps have a part-time 4WD selection, and it is possible to install the locker in the front.

Some vehicle owners install part-time kits or use free wheeling hubs. Free wheeling hubs are anyhow a desired addition to SUV if it’s mainly driven on-road. They improve fuel consumption (axle shaft and differential rotating) and manoeuvrability.

How about noise?

Virtually all automatic lockers make some degree of noise. It is possible to hear a clicking sound from an automatic locker from time-to-time. These clicks are usually inaudible inside the vehicle and generally only occur when the vehicle is making a turn. There are infrequent situations where you may also hear a metallic click which is normal. The “Aussie Locker” is the quietest locker of its type on the market today.

Do I need to install lockers front and rear?

This is a matter of personal preference, money and the end traction requirement. A single “Aussie Locker” will usually double the vehicles off-road ability. A dual installation of lockers can only be described as an “awesome” increase in traction performance.

If only installing one locker should I install in the front or rear?

This is dependent on your personal preference, the type of vehicle, existing diff types, and how you intend to use the vehicle.

- A front installation will usually yield the greatest improvement in off-road capability. This is mainly coming from vehicle weight distribution (more to front axle) and in soft terrain front wheels are driving the trail for rear.

- If a vehicle has an IFS (Independent Front Suspension) system then the front installation will result in a dramatic increase in 4WD capability. This is because all IFS vehicles have very limited suspension movement (wheel travel and articulation) resulting in easily lifted wheels and a loss of front traction. Installing a front locker will solve the deficiency.

- Under full climbing conditions, due to the angle of the vehicle, the rear wheels carry a much greater weight (weight transfer) and therefore, installation in rear is beneficial.

- If a vehicle has LSD (Limited Slip Differential) in the rear, then a front installation provides a significant improvement over the existing LSD and open diff set-up.

- We "Do Not" recommend the installation of a locker in the front of a vehicle that will be driven on icy highways in 4WD without manual hubs.

Will it affect my steering?

Unlike manual lockers which do not provide differential action when locked and severely hamper steering and directional manoeuvrability, the “Aussie Locker’s” smooth and sensitive operation allows differential action resulting in uncompromised steering, uphill or down, soft or hard surfaces. This means that you can select the best route or path and negotiate tight steering bends easily. You can feel a mild tightening in the steering wheel which is a result of both front wheels having incredible traction and driving more equally. There will be a self centering effect on the steering wheel in sand and off-road driving.

We "Do Not" recommend the installation of a locker in the front of a vehicle that will be driven on highways in 4WD without manual hubs. Driving on any slick surface requires additional attention to handling so test your Aussie Locker equipped vehicle in open areas under adverse weather conditions before driving on roads.

A front installation provides the most significant improvement over manual lockers. An “Aussie Locker” is not susceptible to drive line failures and wear present with manual lockers.

How does the Aussie Locker differ from one of the older designed lockers available?

Principal of operation: The Aussie Locker uses a dynamic camming mechanism to stay locked. We use a proprietary design process that ensures that the cam area is not only designed to the tightest tolerances but is also repeatable in high volume machining processes. A competitor’s locker uses interlocking teeth and large springs to stay locked.

Mechanical Design: The Aussie Locker uses approximately half the parts due to a simpler design. It uses fewer parts than any automatic locker on the market today. Fewer parts equal higher reliability.

Case: The Aussie Locker uses the original carrier.

Smoothness of operation: Drive one and you will be able to tell which vehicle has an Aussie Locker.

Degree of sensitivity to unlocking: The Aussie Locker can be unlocked with 1 finger due to the use of 1 high quality bias spring. The locking mechanism is dynamic rather than controlled by large springs.

Amount of backlash: The Aussie Locker has approximately half the backlash (none in the driving teeth).

The cost: The Aussie Locker is more affordable. Compare our pricing to any locker on the market today.

Installation: The Aussie Locker can be installed by almost anyone. The competitors’ locker requires an expensive specialist and special tools.

Time to install: We have found that most vehicle owners can do it themselves in an hour or two.

Warranty: The manufacturer of the “Aussie Locker” provides a two year limited warranty. See the warranty for full details.

Installation documentation: The Aussie Locker comes with detailed installation instructions.

What is product availability

Our aim is to keep most common models in our Estonian warehouse, and we post goods on the same day.

Models that are out of stock will be delivered with 10-15 working days.